4.3 Swinging Servo¶

A Servo is a type of position-based device known for its ability to maintain specific angles and deliver precise rotation. This makes it highly desirable for control systems that demand consistent angle adjustments. It’s not surprising that Servos have found extensive use in high-end remote-controlled toys, from airplane models to submarine replicas and sophisticated remote-controlled robots.

In this intriguing adventure, we’ll challenge ourselves to manipulate the Servo in a unique way - by making it sway! This project offers a brilliant opportunity to dive deeper into the dynamics of Servos, sharpening your skills in precise control systems and offering a deeper understanding of their operation.

Are you ready to make the Servo dance to your tunes? Let’s embark on this exciting journey!

Required Components

In this project, we need the following components.

It’s definitely convenient to buy a whole kit, here’s the link:

Name |

ITEMS IN THIS KIT |

LINK |

|---|---|---|

ESP32 Starter Kit |

320+ |

You can also buy them separately from the links below.

COMPONENT INTRODUCTION |

PURCHASE LINK |

|---|---|

- |

|

Available Pins

Here is a list of available pins on the ESP32 board for this project.

Available Pins |

IO13, IO12, IO14, IO27, IO26, IO25, IO33, IO32, IO15, IO2, IO0, IO4, IO5, IO18, IO19, IO21, IO22, IO23 |

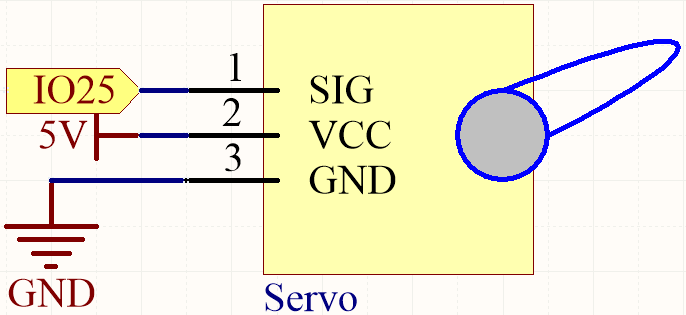

Schematic

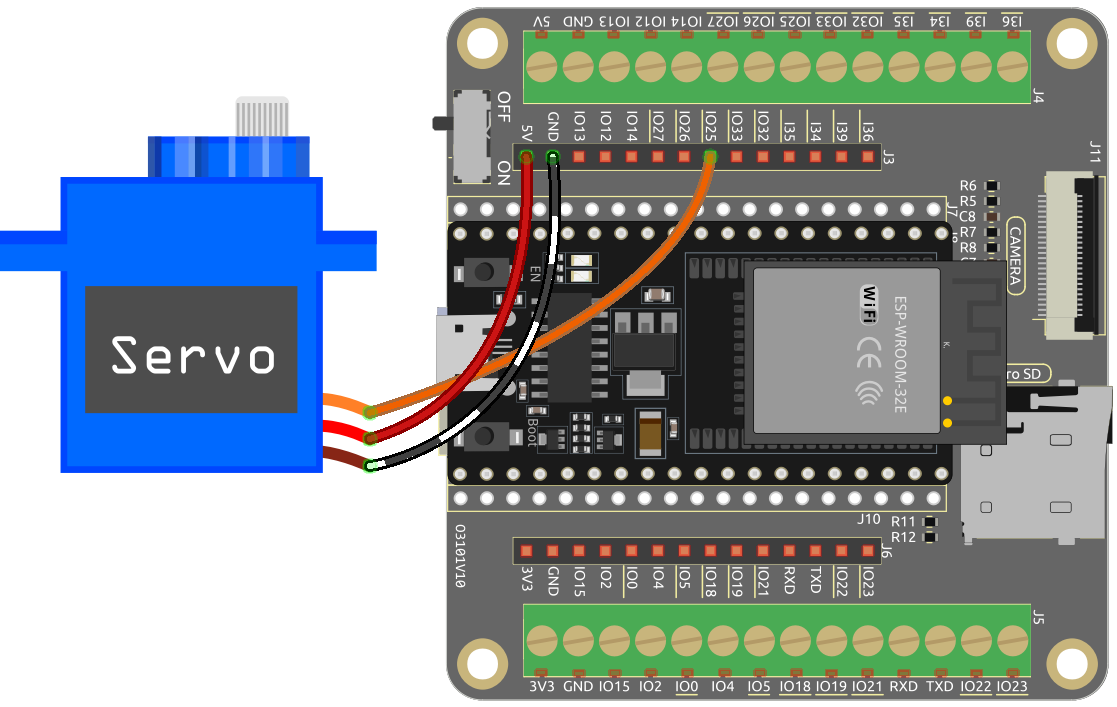

Wiring

Orange wire is signal and connected to IO25.

Red wire is VCC and connected to 5V.

Brown wire is GND and connected to GND.

Code

Note

Open the

4.3_swinging_servo.pyfile located in theesp32-starter-kit-main\micropython\codespath, or copy and paste the code into Thonny. Then, click “Run Current Script” or press F5 to execute it.Make sure to select the “MicroPython (ESP32).COMxx” interpreter in the bottom right corner.

import machine

import time

# Create a PWM (Pulse Width Modulation) object on Pin 25

servo = machine.PWM(machine.Pin(25))

# Set the frequency of the PWM signal to 50 Hz, common for servos

servo.freq(50)

# Define a function for interval mapping

def interval_mapping(x, in_min, in_max, out_min, out_max):

return (x - in_min) * (out_max - out_min) / (in_max - in_min) + out_min

# Define a function to write an angle to the servo

def servo_write(pin, angle):

pulse_width = interval_mapping(angle, 0, 180, 0.5, 2.5) # Calculate the pulse width

duty = int(interval_mapping(pulse_width, 0, 20, 0, 1023)) # Calculate the duty cycle

pin.duty(duty) # Set the duty cycle of the PWM signal

# Create an infinite loop

while True:

# Loop through angles from 0 to 180 degrees

for angle in range(180):

servo_write(servo, angle)

time.sleep_ms(20)

# Loop through angles from 180 to 0 degrees in reverse

for angle in range(180, -1, -1):

servo_write(servo, angle)

time.sleep_ms(20)

When running this code, the servo will continuously sweep back and forth between 0 and 180 degrees.

How it works?

Import the necessary libraries:

machinefor controlling the microcontroller’s hardware, andtimefor adding delays.import machine import time

Create a PWM (Pulse Width Modulation) object on Pin 25 and set its frequency to 50 Hz, which is common for servo.

# Create a PWM (Pulse Width Modulation) object on Pin 25 servo = machine.PWM(machine.Pin(25)) # Set the frequency of the PWM signal to 50 Hz, common for servos servo.freq(50)

Define an

interval_mappingfunction to map values from one range to another. This will be used to convert the angle to the appropriate pulse width and duty cycle.def interval_mapping(x, in_min, in_max, out_min, out_max): return (x - in_min) * (out_max - out_min) / (in_max - in_min) + out_min

Define a

servo_writefunction that takes a PWM object and an angle as inputs. It calculates the pulse width and duty cycle based on the given angle, and then sets the PWM output accordingly.def servo_write(pin, angle): pulse_width = interval_mapping(angle, 0, 180, 0.5, 2.5) # Calculate the pulse width duty = int(interval_mapping(pulse_width, 0, 20, 0, 1023)) # Calculate the duty cycle pin.duty(duty) # Set the duty cycle of the PWM signal

In this function,

interval_mapping()is called to map the angle range 0 ~ 180 to the pulse width range 0.5 ~ 2.5ms.Why is it 0.5~2.5? This is determined by the working mode of the Servo.

Next, convert the pulse width from period to duty.

Since

duty()cannot have decimals when used (the value cannot be a float type), we usedint()to force the duty to be converted to an int type.

Create an infinite loop with two nested loops.

while True: # Loop through angles from 0 to 180 degrees for angle in range(180): servo_write(servo, angle) time.sleep_ms(20) # Loop through angles from 180 to 0 degrees in reverse for angle in range(180, -1, -1): servo_write(servo, angle) time.sleep_ms(20)

The first nested loop iterates through angles from 0 to 180 degrees, and the second nested loop iterates through angles from 180 to 0 degrees in reverse.

In each iteration, the

servo_writefunction is called with the current angle, and a delay of 20 milliseconds is added.